Moving Along with High-Tech Conveyor Systems

As seen in Machine Design. July 14, 2015 If we could climb into a time machine and visit manufacturing facilities

Dorner’s Conveyor Insights are designed to educate users about the latest advances in conveyor technology. Learn from the conveyor experts on the latest industry trends, applications, and unique product offerings. Click the links below to get started learning today!

As seen in Machine Design. July 14, 2015 If we could climb into a time machine and visit manufacturing facilities

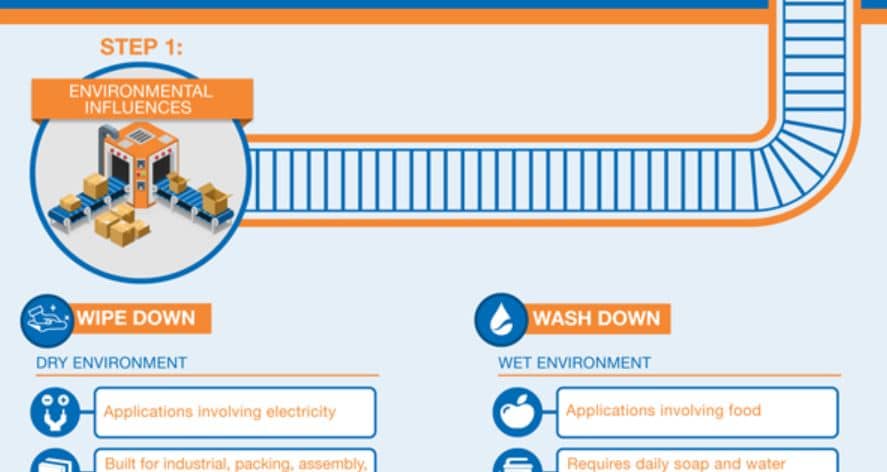

With the vast variety of materials, configurations, accessories, and sizes, choosing a conveyor system can be an overwhelming task. Dorner Conveyor

Quick – name the manufacturers of the conveyors out in your plant. How about the specific series, or types of

Improve Your Packaging Process Growing companies are constantly trying to improve the efficiency and scale of their production services and

In modern manufacturing, where efficiency is the name of the game, conveyance is often one of the primary strategies decision-makers

Who knew that a few inches at work could make all the difference? It may not seem like a lot,

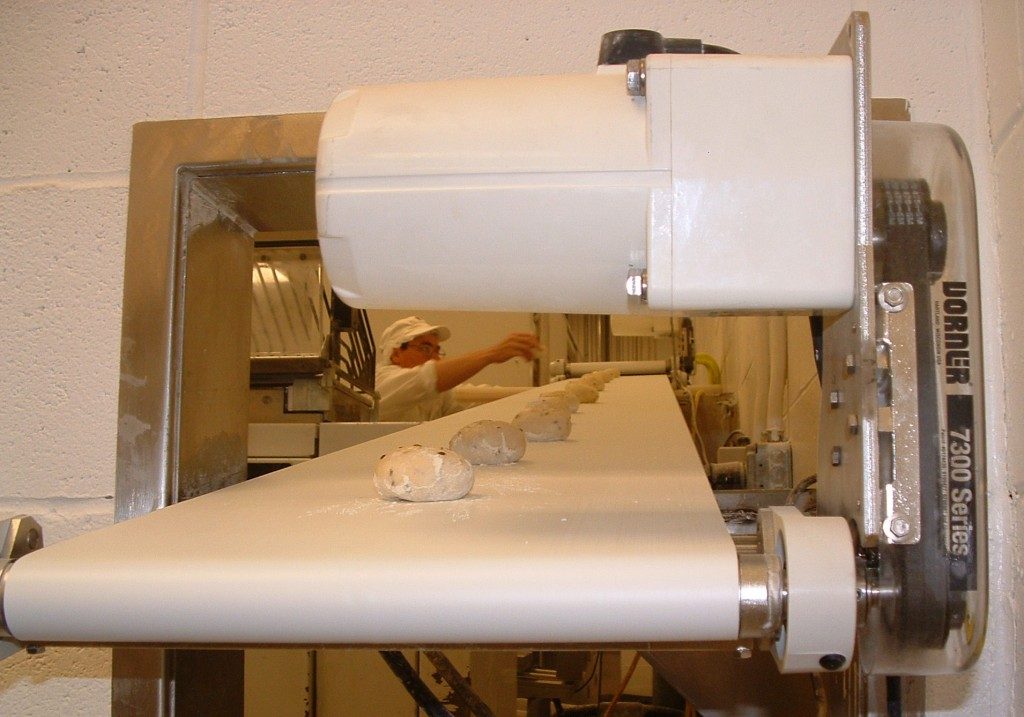

Back in 1996 Pittsburgh-based BreadWorks significantly streamlined its Kaiser roll line by installing new equipment and automating its process. The

Efficiency in manufacturing is heavily influenced by the use of equipment. If equipment isn’t running at peak performance, then it

Demands on production are a driving force behind the conveying industry manufacturing smart technological conveyor system solutions. Today, conveyor systems

Are You Getting the Most Out of Your Sanitary Conveyors? Download our free ebook today! Superior Conveyor Performance Dorner is

It’s hard to put the “honey roast” into honey-roasted nuts when the conveyor system on the processing line doesn’t work

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy